Remaining Strength of Corroded API J55 Steel Casing Pipes

Introduction

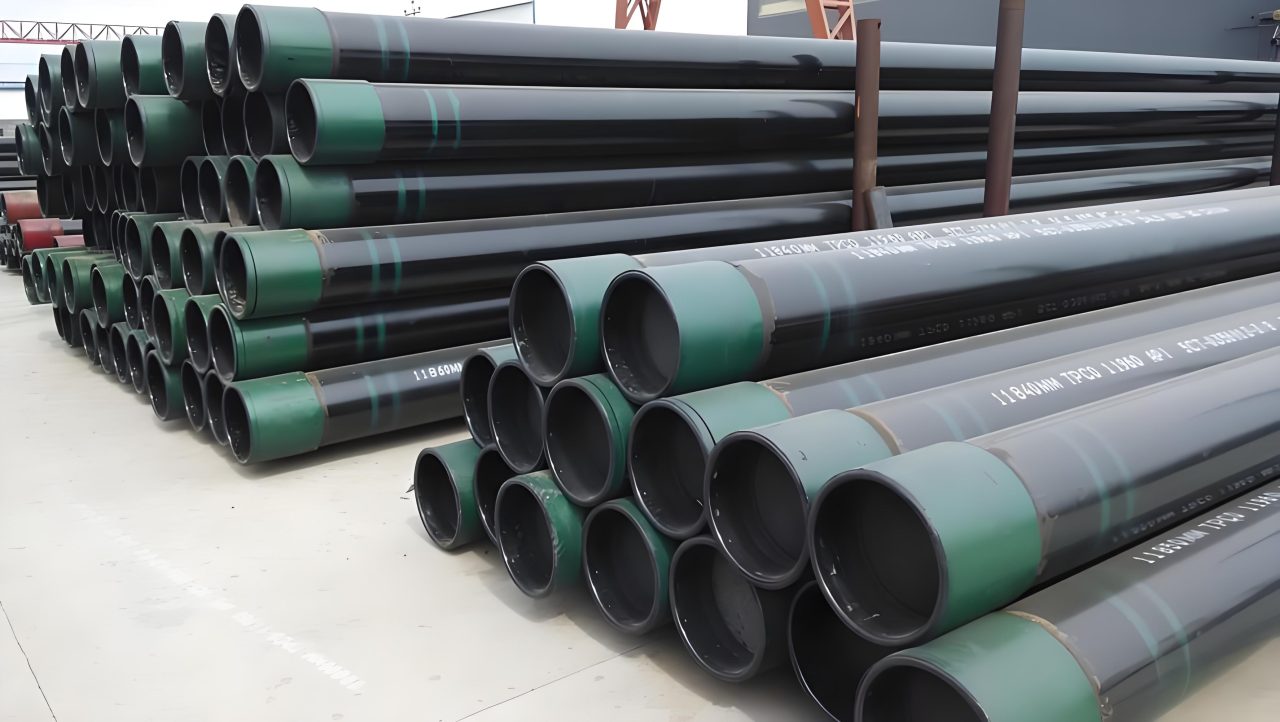

API J55 steel casing pipes are widely used in the oil and gas industry for drilling operations. Over time, these pipes can suffer from corrosion, which affects their structural integrity. Understanding the remaining strength of corroded pipes is crucial for maintaining safety and functionality.

Corrosion in API J55 Pipes

Corrosion is a natural process that deteriorates metal over time due to chemical reactions with the environment. In casing pipes, corrosion can be caused by:

- Chemical Reactions: Interaction with water, CO₂, H₂S, and other chemicals.

- Microbial Activity: Certain bacteria can accelerate corrosion.

- Mechanical Stress: Forces that exacerbate existing corrosion.

Factors Affecting Remaining Strength

- Extent of Corrosion: Depth and spread of corrosion pits or areas.

- Type of Corrosion: Uniform, pitting, or crevice corrosion.

- Material Properties: Original tensile strength and toughness of J55 steel.

- Operating Conditions: Pressure, temperature, and fluid composition.

Assessing Corrosion Damage

Visual Inspection

- Surface Examination: Identifying visible signs of corrosion.

- Ultrasonic Testing: Measuring wall thickness and identifying internal defects.

Quantitative Analysis

- Pit Depth Measurement: Determining the deepest points of corrosion.

- Area of Corrosion: Calculating the corroded area relative to the total surface.

Calculating Remaining Strength

Models and Methods

- B31G Method: A widely used empirical method to predict the remaining strength of corroded pipelines.

- Formula:

Remaining Strength=Original Strength×(1−Corrosion Factor)\text{Remaining Strength} = \text{Original Strength} \times (1 – \text{Corrosion Factor})

- Corrosion Factor: Based on pit depth and pipe dimensions.

- Formula:

- RSTRENG Method: More conservative, accounting for irregular corrosion patterns.

- Advantage: Better suited for pitting corrosion.

- Finite Element Analysis (FEA): Computational modeling to simulate stress distribution.

- Benefits: Detailed insights into stress concentrations and potential failure points.

Case Study: Evaluating API J55 Strength

Scenario Description

- Pipe Specifications: Diameter, thickness, and original material properties.

- Corrosion Data: Pit depths and distribution obtained via inspection.

Analysis Steps

- Data Collection: Gather all relevant measurements and environmental conditions.

- Model Selection: Choose appropriate method (B31G, RSTRENG, or FEA) based on corrosion characteristics.

- Computation: Calculate remaining strength using selected method.

- Interpretation: Assess whether the remaining strength meets safety and operational requirements.

Conclusion and Recommendations

Understanding the remaining strength of API J55 steel casing pipes affected by corrosion is vital for ensuring operational safety and efficiency. Regular inspection, accurate damage assessment, and appropriate analytical methods are key to managing corroded pipelines. It is recommended to:

- Perform Routine Inspections: Regularly monitor for signs of corrosion.

- Use Advanced Modeling Techniques: Employ FEA for complex corrosion patterns.

- Implement Preventive Measures: Apply coatings or inhibitors to reduce corrosion rates.

- Consult Experts: Engage with structural engineers for detailed assessments.