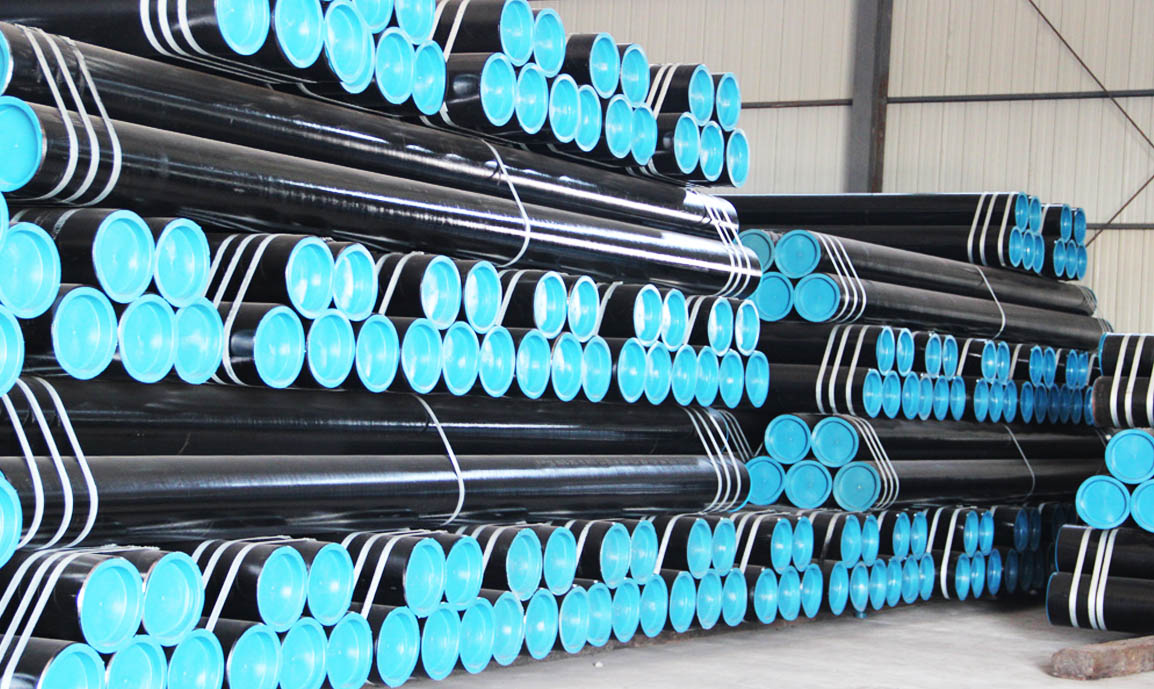

Structural Seamless Steel Pipe

Structural Seamless Steel Pipe

Introduction

Structural seamless steel pipe is a versatile and robust material designed for mechanical and pressure applications. It is also suitable for ordinary uses in steam, water, gas, and air lines. These pipes are highly adaptable, making them ideal for welding and forming operations, including coiling, bending, and flanging. In this article, we will delve into the various aspects of structural seamless steel pipes, including their industry uses, specifications, dimensions, standards, and applications.

Industry Uses of Structural Seamless Steel Pipe

Structural seamless steel pipes are utilized across a wide range of industries due to their strength, durability, and versatility. Some of the main industry uses include:

- Agriculture: Used for irrigation systems, water supply lines, and machinery components. Their ability to withstand high pressure and harsh environmental conditions makes them ideal for agricultural applications.

- Automotive: Relied upon for various components, including exhaust systems, chassis, and suspension parts. These pipes provide the necessary strength and durability to withstand the rigors of automotive applications.

- Construction: Widely used for building frameworks, scaffolding, and structural supports. Their high strength and resistance to deformation make them suitable for heavy-duty construction projects.

- Energy: Used for pipelines, power plants, and renewable energy systems. Their ability to handle high pressure and temperature variations makes them essential for energy applications.

- Machinery: Utilized for various machine components, including hydraulic cylinders, bearings, and structural parts. These pipes offer the necessary precision and strength for high-performance machinery.

- Oil and Gas: Essential for drilling, transportation, and storage of hydrocarbons. These pipes are designed to withstand the extreme conditions of oil and gas exploration and production.

- Shoring: Used to provide temporary support to structures during construction or excavation. Their high load-bearing capacity and stability make them ideal for shoring purposes.

Specifications of Structural Seamless Steel Pipe

Structural seamless steel pipes come in various sizes, schedules, types, lengths, and end finishes to meet the diverse needs of different applications. Here are the key specifications:

- Size Range: 6NB to 1200NB IN

- Schedule: 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS

- Pipe Type: Round, Square, Rectangle, Hydraulic, Honed Tubes

- Length: 5.8/6/11.8/12m, Single Random, Double Random, Cut Length

- End: Plain End, Beveled End

Stainless Steel Seamless Structural Pipe Dimensions

- Type: Seamless steel pipe

- Specification: 114-914MM×4-60MM

- Diameter: 114MM-914MM

- Thickness: 4MM-60MM

- Length: 5.8/6/11.8/12m (or according to requirements)

- Special Pipe: Regular and special thick-walled structure steel pipe, maximum thickness up to 60MM

- Process: Hot rolled and hot expanded

Application

Our high-quality structural steel pipes are highly sought after by customers in the petroleum, natural gas, transportation, and construction industries.

Seamless Structural Pipe Standards

Structural seamless steel pipes are manufactured according to various international standards to ensure quality and performance. Some of the key standards include:

- GB/T Standards:

- GB/T 8162—2008

- GB/T 8163—2008

- ASTM Standards:

- ASTM A106 Gr.B

- ASTM A53 Gr.B

- ASTM A210

- ASTM A333

- DIN Standards:

- DIN1629

- DIN2448

- DIN17175

- EN Standards:

- EN10216

- EN10204

- EN10297

Material

- 20#

- Q345B

- ST52

- S355JRH

- ST37

- 10#

- A106/A53 GR.B

Application & Specification (Seamless)

- Oil & Gas Sector:

- API 5L

- API 5CT

- IS 1978, 1979

- Automotive Industry:

- ASTM A-519

- SAE 1010, 1012, 1020, 1040, 1518, 4130

- DIN 2391, 1629

- BS 980, 6323 (Pt-V)

- IS 3601, 3074