Structures Steel Pipe

Steel Pipe for Structures

High-quality mechanical steel pipe for construction and industrial machinery, and other structural applications.

To meet the requirements for a broad range of applications and processing conditions, including the latest and most demanding uses, Abter steel pipe products for machine structures are manufactured using a wealth of experience accumulated over many decades, as well as the very latest equipment and most rigorous quality control.

Our product range includes not only carbon steel pipe for machine structures, alloy steel pipe, carbon steel material for machine structures, and alloy steel material for machine structures that conform to ASTM, but also a wide range of high-strength steel pipe products made to our own quality standards using a wide range of manufacturing methods, including seamless pipe, electric resistance welded (ERW) pipe, and hot finished ERW pipe.

A252 Grade 1, 2 & 3 Structural Grade Steel Pipe

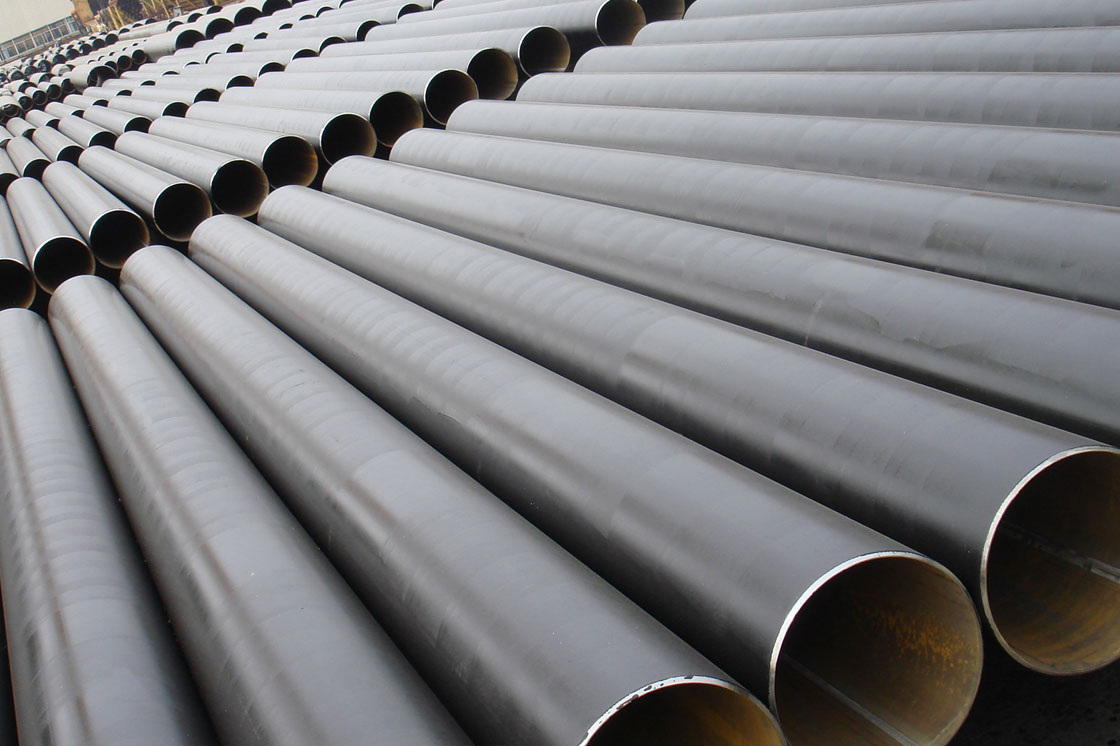

We custom fabricate and sell pipe to customers serving construction segments such as building construction, road construction, bridge construction, utility construction, marine construction, and oilfield construction just to name a few. Our Welded Steel Pipe finished products are installed by those performing horizontal road boring, directional drilling, and pile driving procedures for these industries. We have two specialty niches. The first includes fabricating 20′ dead length stock sections for use as Steel Casings, such as Road Bore casing, Culvert casing, Open Cut casing, Open Tunnel casing, and Water Well casing. The picture above shows some of these 20′ sections on our yard. The second includes custom fabricating Steel Pipe Pilings, such as Foundation piling, Bridge piling, and Marine piling, including pier pilings, dock pilings, and deep water pipe pilings to length.

Abter Pipe produces round submerged arc welded steel tubing to meet ASTM specifications A252 Grade 1, Grade 2 and Grade 3. The purpose and strength levels required will determine which grade is required. Produced in 12.375 inch, 14.00 inch and 16.00 inch OD and in wall thicknesses from 0.109″ up to 0.220″, Abter’s A252 tubing is used in a select number of agricultural, industrial and construction related end uses. For a complete listing of all tubing sizes produced by Abter, please visit our Steel Tubing Product Catalog.

Physical Requirements

Below are the physical properties required to meet the three grades that we produce ASTM A252 round tubing to.

| Grade | Yield (min) | Tensile (min) | Elongation (min) |

| Grade 1 | 30,000 psi | 50,000 psi | Determined by wall |

| Grade 2 | 35,000 psi | 60,000 psi | Determined by wall |

| Grade 3 | 45,000 psi | 66,000 psi | Determined by wall |

Weld Seam Information

Specification Notes

- According to ASTM A252, the outside diameter of tubes produced to this specification shall have a +/- 1% variation.

- At the time of quote and order placement, please specify the end use of the tubing and how the tubing will be used so that it can be determined whether the submerged arc weld will be acceptable for the application.

- All other mechanical tubing sizes produced by Abter up to 12.75″ round and 6.00″ square and rectangle are produced as electric resistance welded (ERW) tubing..

- For more detailed information on the A252 specification and to purchase a copy of it, please visit the ASTM website.

ASTM A500 STRUCTURAL WELDED PIPE

ASTM A500 structural pipe is a standard specification for cold-formed welded structural tubing produced to round nominal pipe sizes. ASTM A500 is the most common specification in The world for Hollow Structural Sections. Since ASTM A500 is a structural specification, round pipe HSS produced to this specification is a fit for applications being used in structural applications and general construction use. The tolerances of A500 are tighter than those of A53, therefore the A500 round pipe HSS has more quality and less variability than A53. Round HSS pipe has a superior surface finish and does not come with a lacquer coating. A500B Structural Pipe is manufactured for use in applications that demand greater strength, closer tolerances, and a superior finish.

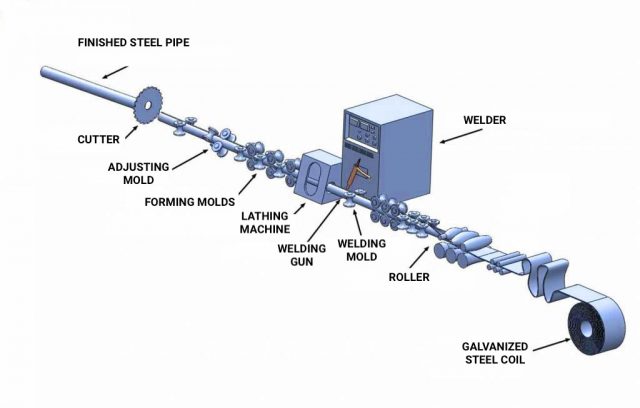

MANUFACTURING PROCESS

ASTM A500 structural pipe is welded pipe sized tubing made from flat-rolled steel, formed through a roller system and welded using electric-resistance welding. Longitudinal butt joints of welded tubing shall be welded across its thickness in such a manner as to assure the structural design strength of the tubing section. Welded structural steel pipe is normally furnished without the removal of inside flash.

Square & Rectangle Pipe

Below are physical properties required to meet the three grades that we produce ASTM A500 square, rectangle and special shaped tubing to. A flattening test is not a standard requirement for non-round pipe produced to A500.

| Grade | Yield (min) | Tensile (min) | Elongation (min) |

| Grade A | 39,000 psi | 45,000 psi | Determined by wall |

| Grade B | 46,000 psi | 58,000 psi | Determined by wall |

| Grade C | 50,000 psi | 62,000 psi | Determined by wall |

Round Pipe

Below are physical properties required to meet the three grades that we produce ASTM A500 round pipe to. A flattening test is also a standard requirement for round tubing produced to the A500 specification.

| Grade | Yield (min) | Tensile (min) | Elongation (min) |

| Grade A | 33,000 psi | 45,000 psi | Determined by wall |

| Grade B | 42,000 psi | 58,000 psi | Determined by wall |

| Grade C | 46,000 psi | 62,000 psi | Determined by wall |

ASTM Galvanized structure steel pipe

| Product name | Hot dipped galvanized steel pipe |

| Material | Carbon Steel |

| Size | OD: 21-273MM

THICKNESS: 1.0-10.0MM LENGTH: 5.5-6.5M |

| Grade | Q195 = S195 / A53 Grade A Q235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2 Q345 = S355JR / A500 Grade B Grade C |

| Standard | EN10210 S235JRH, S275J0H,S275J2H, S355J0H, S355J2H, S275NH, S355NH, S275NLH, S355NLH. |EN39, BS1139, BS1387, EN10255, ASTM A53, ASTM A500, A36, ASTM A795, ISO65, ANSI C80, DIN2440, JIS G3444, GB/T3091, GB/T13793 |

| Surface | Zinc coating 200-500g/m2 (30-70um) |

| Ends | Plain ends

with or without caps |

| Usage | construction / building materials steel pipe, structure steel pipe,

scaffolding pipe, fence post steel pipe, fire sprinkler steel pipe, greenhouse pipe |

– The surface is shiny and beautifully patterned.

– High durability and perfect pressure resistance thanks to the thick Zinc layer (Z12 – Z18), increased corrosion resistance and inner layer protected for a longer period.

|

Product Quality

|

JIS G, ASTM International,

AS/NZS International Standard |

|

Technology for Galvanized Square Steel Pipes

|

Modern machinery and advanced technology are applied to save energy and reduce production cost.

|

|

Production Process for Galvanized Square Steel Pipes

|

Closed from raw material to final product. |

|

Annual Production Capacity for Galvanized Square Steel Pipes

|

400,000 tons of pipe products.

60,000 panels/gates/fences & other end products. |

|

Quality Management for Galvanized Square Steel Pipes

|

ISO 9001:2008 Standard. |

PRODUCT LINE FOR GALVANIZED STEEL PIPE

With a closed production line system equipped with modern technology from Europe, Japan, Korea, Taiwan, Chinh Dai Steel always ensure the best quality of galvanized steel pipes supervised by Quality Management System ISO 9001: 2008.

ADVANCED TECHNOLOGY FOR GALVANIZED STEEL PIPE

Chinh Dai Steel applies seven technology steps. Modern machinery and advanced technology used to make galvanized steel pipes contribute to save energy and reduce production costs. The production process is closed from raw material to final product. Each production stage uses a separate and modern production line.

With modern and closed production line, strict quality control from input to output, Chinh Dai’s steel pipe is always ensured the best quality, accurate thickness, and surface size.

MANUFACTURING PROCESS FOR GALVANIZED STEEL PIPE