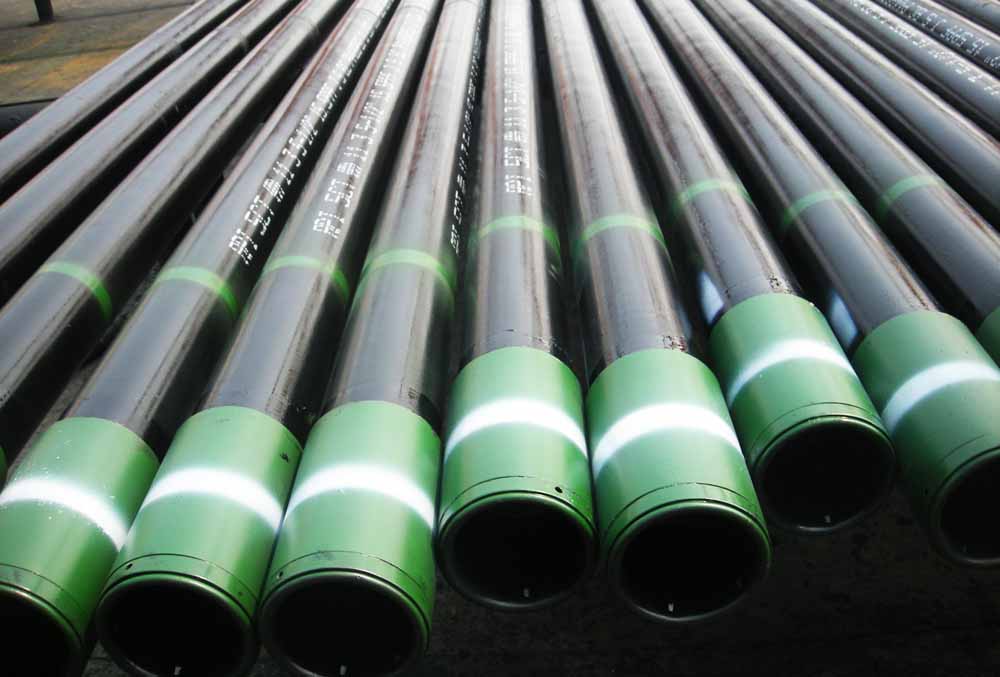

API 5CT Casing Pipe For Oilfield

A casing pipe is a hollow steel tube that is typically rammed into place through the earth by using a hydraulic or pneumatic jack. After being driven, the displaced soil is removed and the product pipe, or carrier pipe, is inserted inside the steel tube. Available Sizes Category:ERW, HFW or SMLS Standards:API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q,API 5CT PSL1/PSL2 L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125 Steel Grade:H40, J55, K55, N80

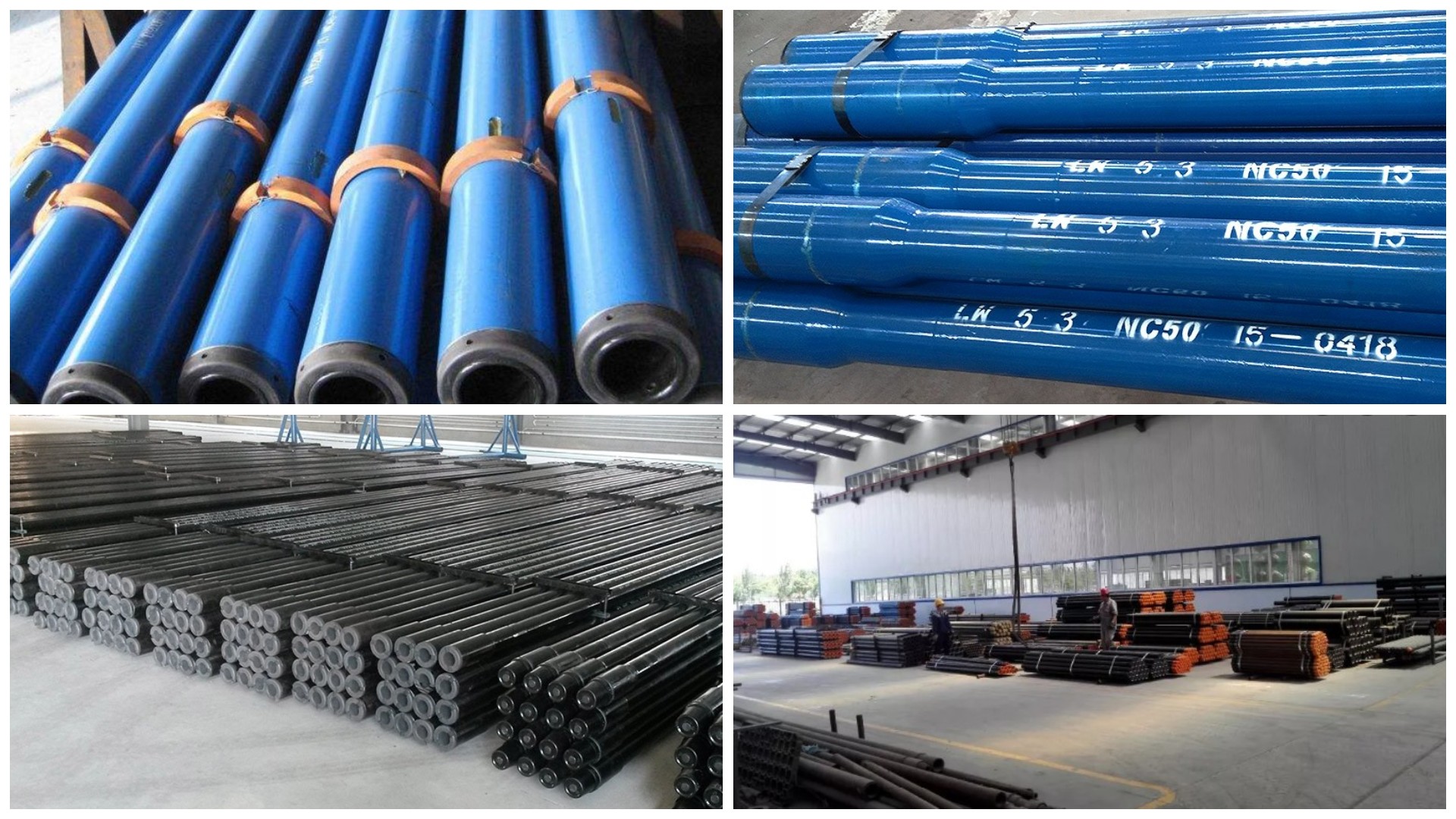

Drill Collar | Slick & Spiral Type , Non-magnetic Drill Collar

Drill collars are a fundamental component of the drill string, providing the necessary weight, stability, and direction control for effective drilling operations. Their various types and customizable dimensions allow for versatile applications in different drilling environments. By enhancing drilling efficiency, improving wellbore quality, and reducing equipment wear, drill collars contribute significantly to the success of drilling projects.

Drill pipe | API 5DP & Heavy Weight type Drill

Our range of drill pipes and accessories are designed to meet the rigorous demands of oil and gas well drilling, as well as other drilling applications such as mining, geothermal, and water wells. We offer a variety of sizes, grades, and configurations to suit different needs and conditions. Our products comply with the highest industry standards, ensuring reliability, durability, and performance. For more information on our products or to discuss your specific requirements, please contact us. We are dedicated to providing high-quality drilling solutions tailored to your needs.

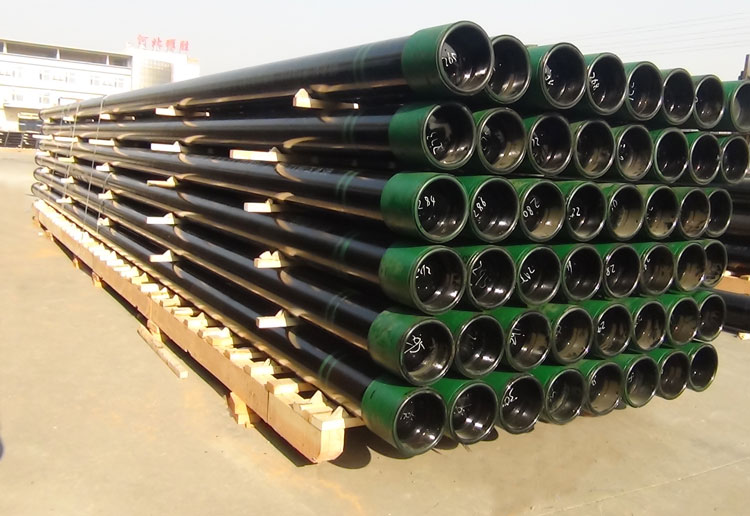

API 5CT H40 octg casing pipe

H40 casing steel pipes are essential components in the drilling and production of oil and gas wells. These pipes are manufactured to meet API Spec 5CT standards, ensuring quality, performance, and reliability. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, H40 casing pipes deliver dependable performance in various drilling and production environments.

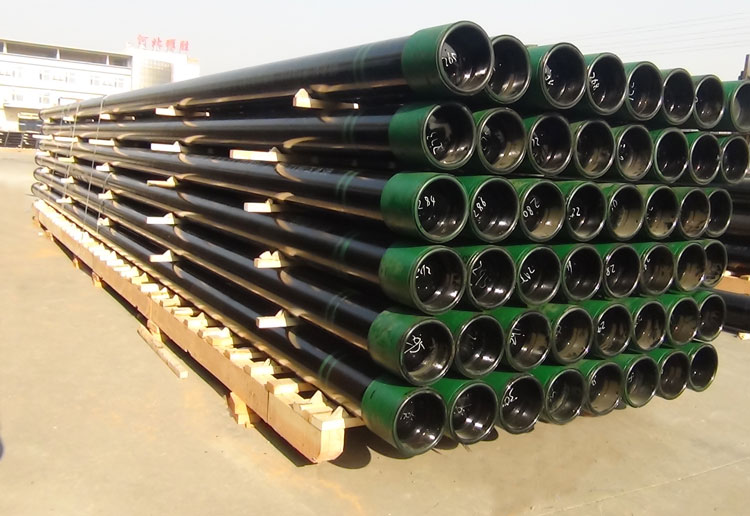

API 5CT J55 CASING & TUBING

The American Petroleum Institute specification API 5CT J55 Pipe is designed for use in the oil and gas industry. API 5CT J55 is a commonly used petroleum casing pipe material. It is produced according to the API 5CT standard and used in a variety of well types, both oil and natural gas. The main purposes of using casing or tubing are to protect the wellbore from collapse and to provide a conduit for well fluids. The casing is placed in the well first, followed by tubing, which is often smaller in diameter and thus can be nested inside the casing. Both casing and tubing must be made from strong materials that can withstand the high pressures and temperatures encountered deep underground. API 5CT J55 meets these requirements and is, therefore, an excellent choice for OCTG (oil country tubular goods) applications. It is typically produced as seamless steel pipe, but can also be procured in welded form. API 5CT J55 has a relatively high yield strength and good fatigue resistance, making it an ideal choice for high-pressure, high-load applications such as petroleum products.

K55 Casing Tubing

API 5CT K55 is a pipe grade specified by the American Petroleum Institute. API 5CT K55 is a type of well casing that is typically used in well drilling operations. The casing and tubing are OCTG (oil country tubular goods) that are used to form the walls of the well. The steel pipe is placed in the well and held in place by cement. The cement helps to protect the well from collapse and keeps the well fluids from escaping. API 5CT K55 is a popular choice for well drilling because it is durable and can withstand high temperatures and pressures.