FBE Coated Pipe

FBE coated pipes offer robust protection against corrosion and mechanical damage, making them ideal for a variety of industrial applications, including oil and gas pipelines, water pipelines, and more. Understanding the coating process, properties, and benefits can help in selecting the right coated pipe for specific needs, ensuring long-term performance and reliability in challenging environments.

IPN8710 Anticorrosion Steel Pipe

IPN8710 is an advanced anticorrosion coating designed for steel pipes, combining polyurethane resin, modified epoxy resin, asphalt, anti-rust pigments, and various additives. This coating provides exceptional corrosion resistance and durability, making it ideal for environments where steel pipes are exposed to water, gas, or other corrosive substances. By leveraging the benefits of IPN8710 coated pipes, industries can achieve enhanced pipeline integrity, reduced maintenance costs, and extended service life, ensuring safe and efficient operation in various water transport applications.

3LPE / 3LPP Coated Pipe

3LPE (Three-Layer Polyethylene) and 3LPP (Three-Layer Polypropylene) coatings are advanced pipe coating technologies used to protect steel pipes from corrosion, mechanical damage, and other environmental factors. These coatings are widely used in various industries, including oil and gas, water supply, and chemical processing.

2LPE / 2LPP Coated Pipe

2LPP coated pipes offer a superior solution for protecting steel pipelines from corrosion and mechanical damage, especially in high-temperature and chemically aggressive environments. By leveraging the properties of fusion bonded epoxy and polypropylene, these pipes ensure long-term durability, reduced maintenance costs, and enhanced performance in critical applications. The development of polypropylene materials has significantly contributed to advancing pipeline coating technologies, providing reliable and efficient solutions for modern infrastructure needs.

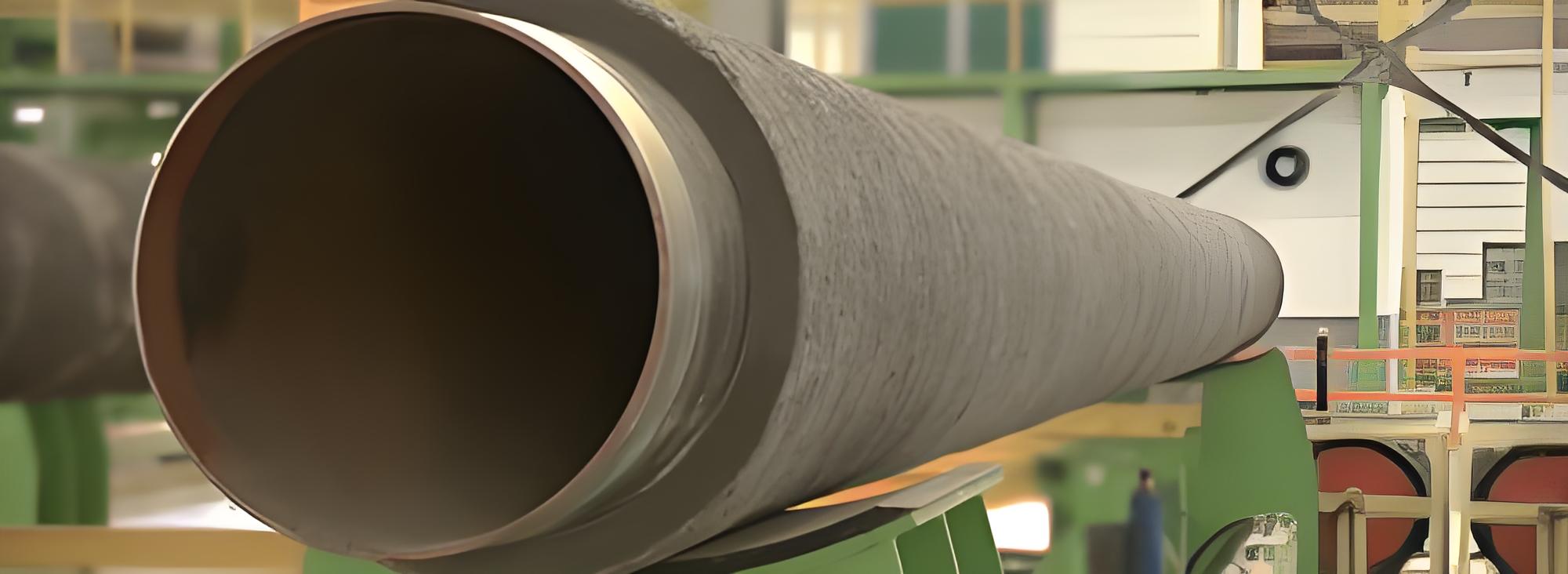

Concrete Weight Coated Pipe CWC

Concrete weight coated pipes provide essential benefits for subsea and offshore pipeline applications, including negative buoyancy, mechanical protection, and durability. By adhering to strict standards and quality control during manufacturing, these pipes ensure reliable performance and long-term

Galvanized Steel Pipe – Hot Dip Galvanized Steel Pipe

When choosing between hot-dip galvanizing and pre-galvanizing, consider the environmental conditions and the specific requirements of your application. Hot-dip galvanizing offers superior protection for harsh environments due to its thicker coating, while pre-galvanizing is a cost-effective solution for less demanding conditions. Both methods, when adhering to standards like ASTM A525, provide reliable corrosion protection for steel components.