Tubing Casing Coupling

Tubing Coupling & Casing Coupling

Introduction

In the oil and gas industry, couplings are critical components used to connect joints of casing and tubing. These connections ensure the structural integrity and continuity of the pipe string, facilitate the transport of fluids, and help maintain well integrity.

Tubing Coupling

Overview

Tubing couplings are used to connect joints of tubing, which are smaller-diameter pipes that transport oil and gas from the production zone to the surface. Normally tubing coupling OD maximum is 4 1/2”, as the tubing pipe is applied for the drilling activities (Inside the tubing is the sucker rod to drill/pump the oil), couplings type is more various and rigorous than casing, mostly used is thicken type upset coupling (Internal upset and external upset), for short is EUE coupling, it is the most favorable in tubing connections. Tubing with EU end (EUE) coupling connection also called UPTBG. Because of the end of the tubing is thickened (upset), the connecting stress is better than buttress coupling.Buttress coupling another type used for tubing connections, it has the same thickness of the pipe body, called NU end (NUE)tubing or TBG.

Specifications

- Diameter: Typically ranges from 1.9 inches to 4.5 inches.

- Length: Shorter than the tubing joints, usually a few inches long.

- Material Grade: Matches the grade of the tubing, such as J-55, N-80, L-80, and P-110.

- Thread Types: Includes API Round Thread and premium connections designed for enhanced performance.

Functions

- Connection: Joins two joints of tubing to form a continuous string.

- Sealing: Ensures a leak-proof seal to prevent fluid migration.

- Strength: Maintains structural integrity under various loads and pressures.

Applications

- Production Tubing: Used in the production phase to transport hydrocarbons from the reservoir to the surface.

- Injection Wells: Used for injecting fluids into the reservoir to enhance recovery.

Example

A typical tubing coupling might have the following specifications:

- Outer Diameter: 3.5 inches

- Grade: L-80

- Thread Type: API Round Thread

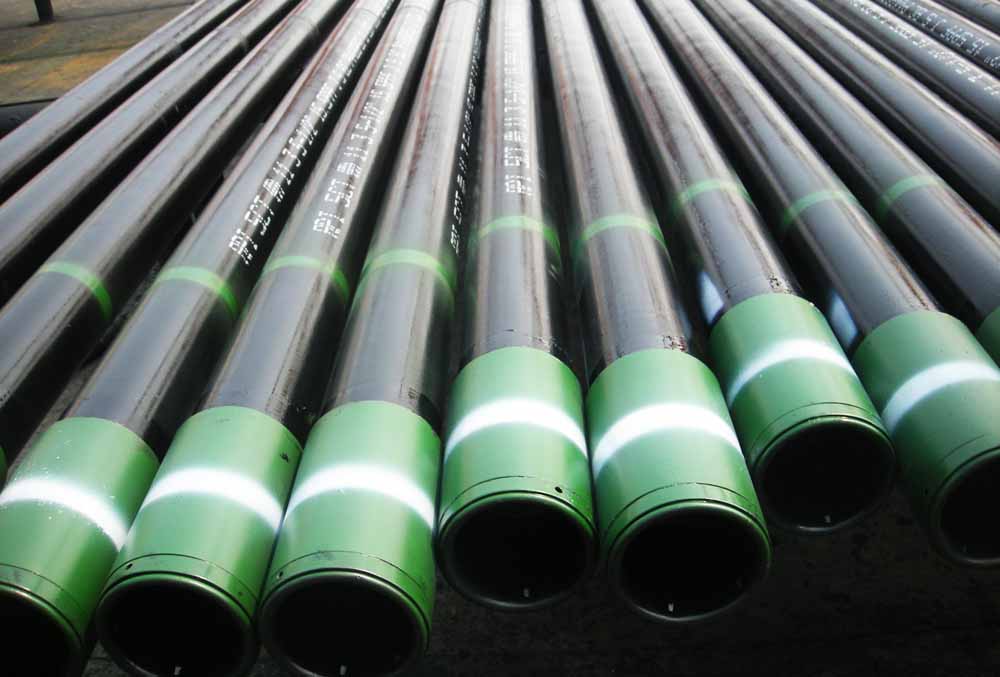

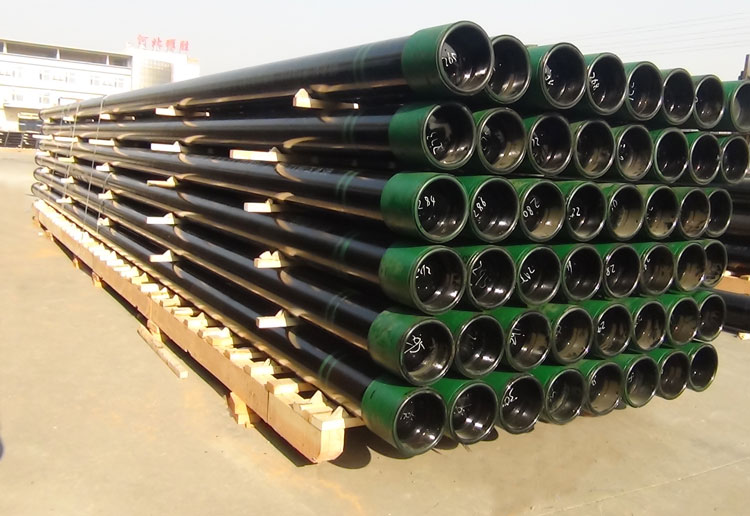

Casing Coupling

Overview

Casing couplings are used to connect joints of casing, which are larger-diameter pipes that stabilize the wellbore, control formation pressures, and prevent wellbore collapse.Casing coupling is for the dimensions more than 4 1/2 inch. Differently than tubing coupling is, casing coupling normally does not need to be thickened (Non-upset), which means no upset casing coupling, so it has following types:

Specifications

- Diameter: Typically ranges from 4.5 inches to 20 inches.

- Length: Shorter than the casing joints, usually a few inches long.

- Material Grade: Matches the grade of the casing, such as H-40, J-55, N-80, and P-110.

- Thread Types: Includes API Buttress Thread, API Round Thread, and premium threads for high-performance applications.

Functions

- Connection: Joins two joints of casing to form a continuous string.

- Sealing: Ensures a leak-proof seal to prevent fluid migration.

- Strength: Maintains structural integrity under various loads and pressures.

Applications

- Surface Casing: Protects freshwater zones and provides a foundation for blowout preventers.

- Intermediate Casing: Isolates problematic formations and provides additional pressure control.

- Production Casing: Runs from the surface to the production zone, ensuring well integrity during production.

Example

A typical casing coupling might have the following specifications:

- Outer Diameter: 13.375 inches

- Grade: N-80

- Thread Type: API Buttress Thread

Comparison

| Feature | Tubing Coupling | Casing Coupling |

|---|---|---|

| Primary Function | Connects joints of tubing | Connects joints of casing |

| Typical Diameter | 1.9″ – 4.5″ | 4.5″ – 20″ |

| Length | Shorter than tubing joints | Shorter than casing joints |

| Material Grade | J-55, N-80, L-80, P-110 | H-40, J-55, N-80, P-110 |

| Thread Types | API Round Thread, premium connections | API Buttress Thread, API Round Thread, premium threads |

| Application | Production tubing, injection wells | Surface casing, intermediate casing, production casing |

Seamless and ERW Casing

| Specification | API 5CT |

| Grades | K55, N80, L80, C95, P110, Chrome, J55(Modified), J55 (API), PS80 |

| Special Grades | For sour services and for deep well with high collapse properties |

| Dimensions | OD 4″ – 26″ WT – 0.2 -0.5″ |

| Length range | 1, 2 or 3 |

| Thread connections | API (STC and LTC), BTC, extreme line, etc. |

Seamless and ERW Tubing

| Specification | API 5CT |

| Grades | J55 (API) J55(Modified), N80, L80, L80 13Cr, P110, Q125, H40 (API) |

| Thread connections | API 5B – Last Edition or Premium, EUE, NUE, special seal, metal-to-metal seal and VAGT |

Casing Couplings Short Thread Specifications:

| Casing Couplings Short Thread |

Casing Size OD (inches) | Coupling Size OD (inches) | Length (inches) | Weight per Coupling (lbs) | Palletized Carton Quantity | Palletized Carton Weight |

|

4-1/2 | 5.000 | 6.250 | 8.05 | 343 | 2716 |

| 5 | 5.563 | 6.500 | 10.18 | 210 | 2168 | |

| 5-1/2 | 6.050 | 6.750 | 11.44 | 216 | 2501 | |

| 6-5/8 | 7.390 | 7.250 | 19.97 | 115 | 2322 | |

| 7 | 7.656 | 7.250 | 18.34 | 120 | 2231 | |

| 7-5/8 | 8.500 | 7.500 | 26.93 | 80 | 2322 | |

| 8-5/8 | 9.625 | 7.750 | 35.58 | 60 | 2132 | |

| 9-5/8 | 10.625 | 7.750 | 39.51 | 50 | 2006 | |

| 10-3/4 | 11.750 | 8.000 | 49.61 | 45 | 2079 | |

| 11-3/4 | 12.750 | 8.000 | 50.49 | 35 | 1767 | |

| 13-3/8 | 14.375 | 8.000 | 56.23 | 25 | 1436 | |

| 16 | 17.000 | 9.000 | 78.98 | 20 | – | |

| 18-5/8 | 20 | 9.000 | 118.94 | 10 | – | |

| 20 | 21.000 | 9.000 | 98.25 | 10 | – |

Casing Couplings Long Thread Specifications

| Casing Couplings Long Thread |

Casing Size OD (inches) | Coupling Size OD (inches) | Length (inches) | Weight per Coupling (lbs) | Palletized Carton Quantity | Palletized Carton Weight |

|

4-1/2 | 5.000 | 7.000 | 9.07 | 294 | 2697 |

| 5 | 5.563 | 7.750 | 12.56 | 210 | 2573 | |

| 5-1/2 | 6.050 | 8.000 | 14.03 | 180 | 2555 | |

| 6-5/8 | 7.390 | 8.750 | 24.82 | 100 | 2315 | |

| 7 | 7.656 | 9.000 | 23.67 | 100 | 2351 | |

| 7-5/8 | 8.500 | 9.250 | 34.23 | 80 | 2807 | |

| 8-5/8 | 9.625 | 10.000 | 47.48 | 48 | 2337 | |

| 9-5/8 | 10.625 | 10.500 | 55.77 | 40 | 2302 | |

| 10-3/4 | 11.750 | * 10.500 | * 62.38 | 45 | * 36 | |

| 11-3/4 | 12.750 | * 10.500 | * 67.59 | 30 | * 24 | |

| 13-3/8 | 14.375 | * 10.500 | * 76.63 | 25 | * 20 | |

| 16 | 17.000 | * 11.000 | * 96.55 | 20 | * 16 | |

| 18-5/8 | 20.000 | – | – | 10 | 8 | |

| 20 | 21.000 | * 11.500 | * 126.74 | 10 | 8 | |

| * NOT API SPECIFICATIONS. | ||||||

Casing Coupling – Buttress Thread

| Casing Couplings Buttress Thread |

Casing Size OD (inches) | Coupling Size OD(inches) | Length (inches) | Weight per Coupling (lbs) | Palletized Carton Quantity | Palletized Carton Weight |

|

4-1/2 | 5.000 | 8.875 | 10.11 | 196 | 2007 |

| 5 | 5.563 | 9.125 | 12.99 | 144 | 2840 | |

| 5-1/2 | 6.050 | 9.250 | 14.14 | 144 | 2061 | |

| 6-5/8 | 7.390 | 9.625 | 24.46 | 92 | 2295 | |

| 7 | 7.656 | 10.000 | 23.22 | 80 | 2068 | |

| 7-5/8 | 8.500 | 10.375 | 64.84 | 64 | 2221 | |

| 8-5/8 | 9.625 | 10.625 | 45.94 | 48 | 2414 | |

| 9-5/8 | 10.625 | 10.625 | 50.99 | 40 | 2256 | |

| 10-3/4 | 11.750 | 10.625 | 56.68 | 36 | 2307 | |

| 11-3/4 | 12.750 | 10.625 | 61.74 | 24 | 2179 | |

| 13-3/8 | 14.375 | 10.625 | 69.95 | 20 | 1429 | |

| 16 | 17.000 | 10.625 | 87.56 | 16 | – | |

| 18-5/8 | 20.000 | 10.625 | 138.03 | 8 | – | |

| 20 | 21.000 | 10.625 | 110.33 | 8 | – |

Tubing Couplings – External Upset End (EUE):

| EUE Tubing Couplings |

Casing Size OD (inches) | Coupling Size OD (inches) | Threads per inch | Length (inches) | Weight per Coupling (lbs) | Palletized Carton Quantity | Palletized Carton Weight |

|

1.90 | 2.500 | 10 Round | – | 1.85 | – | – |

| 2-3/8 | 3.063 | 8 Round | 4.875 | 3.42 | 1,444 | 3942 | |

| 2-7/8 | 3.668 | 8 Round | 5.500 | 5.29 | 792 | 4220 | |

| 3-1/2 | 4.500 | 8 Round | 5.750 | 9.02 | 448 | 3860 | |

| 4 | 5.000 | 8 Round | – | 10.62 | 392 | – | |

| 4-1/2 | 5.563 | 8 Round | 6.500 | 13.31 | 252 | 3456 |

Tubing Couplings – Non Upset End (NUE)

| Non-Upset Tubing Couplings |

Casing Size OD (inches) | Coupling Size OD (inches) | Threads per inch | Length (inches) | Weight per Coupling (lbs) | Palletized Carton Quantity | Palletized Carton Weight |

|

1.90 | 2.200 | 10 Round | 3.750 | 1.85 | – | – |

| 2-3/8 | 2.875 | 10 Round | 4.500 | 2.82 | 1,512 | 4264 | |

| 2-7/8 | 3.500 | 10 Round | 5.500 | 5.15 | 800 | 4120 | |

| 3-1/2 | 4.250 | 10 Round | 5.625 | 8.17 | 502 | 4101 | |

| 4 | 4.75 | 8 Round | 5.75 | 9.57 | 392 | – | |

| 4-1/2 | 5.200 | 8 Round | 6.500 | 10.76 | 252 | 2712 |

Coupling Pipe Grade Identification By Paint Color

| Coupling colour code | |||||

| Grade | Grade Type | Colour(s) for Coupling | Number andcolour of bands

for product |

Picture | |

| EntireCoupling | Band(s) | ||||

| H40 | None | Same as for pipe | None/black band at the manufacturer’s option | ||

| J55 Tubing | Bright Green | None | One Bright Green | ||

| J55 Casing | Bright Green | One White | One Bright Green | ||

| K55 | Bright Green | None | Two Bright Green | ||

| M65 | M65Pipe uses L80Type 1Couplings | One Bright GreenOne Blue | |||

| N80 | 1 | Red | None | One Red | |

| N80 | Q | Red | One Green | One RedOne Bright Green | |

| R95 | Brown | None | One Brown | ||

| L80 | 1 | Red | One Brown | One RedOne Brown | |

| L80 | 9Cr | None | Two Yellow | One Red,One Brown,

Two Yellow |

|

| L80 | 13Cr | None | One Yellow | One Red,One Brown,

One Yellow |

|

| C90 | 1 | Purple | None | One Purple | |

| T95 | 1 | Silver | None | One Silver | |

| C110 | White | Two Brown | One White,Two Brown | ||

| P110 | White | None | One White | ||

| Q125 | Orange | None | One Orange | ||

Inquiry Online

Conclusion

Tubing and casing couplings are essential components in the construction and operation of oil and gas wells. Tubing couplings connect smaller-diameter tubing used for transporting hydrocarbons, while casing couplings connect larger-diameter casing used to stabilize the wellbore and control formation pressures. Selecting the appropriate couplings based on diameter, material grade, and thread type is crucial to ensure well integrity, safety, and efficient operation.