What are some of the most commonly used scaffold tubes and pipes?

In the construction industry, scaffold tubes and pipes are essential components used to create the framework of scaffolding structures. These tubes and pipes provide the necessary support and stability for workers and materials at elevated heights. Here are some of the most commonly used scaffold tubes and pipes:

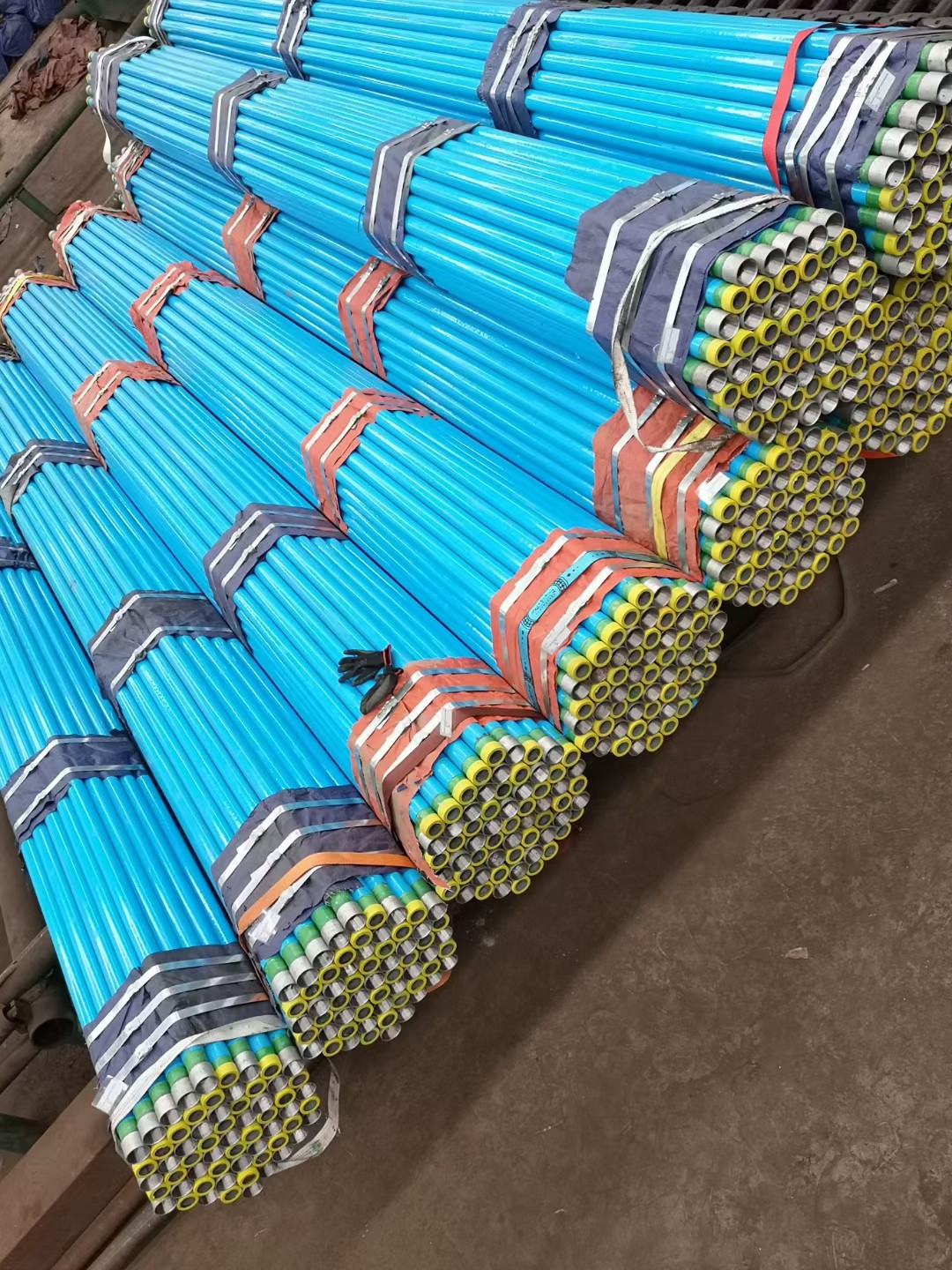

Galvanized scaffold tube

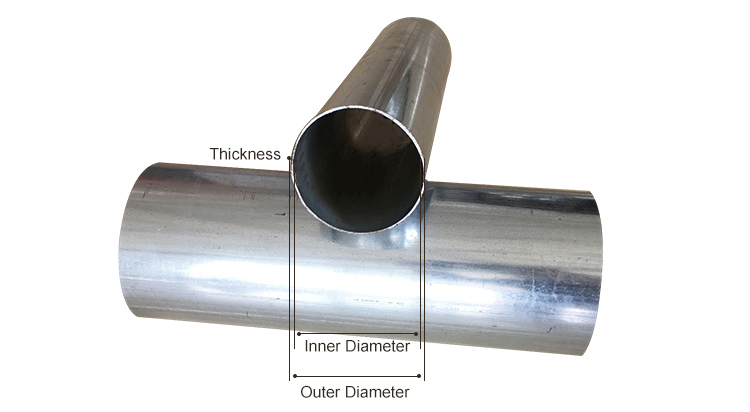

| Name | international standard galvanized steel pipe round pipe |

| Standard | JIS G3466, EN 10219, GB/T 3094-2000, GB/T 6728-2002 |

| Material | Q195,Q215,Q235 |

| Size | 15*15-100*100mm |

| WT | 0.6-2.3mm |

| Surface treatment | Pre-galvanized |

| Zinc coating | 60-80g/m2, can up to 120g/m2 |

| Length | usually 4.5-6.5m, can up to 12m; and can cut in any length according to client’ s requirements |

| End Treatment | plain or bevelled |

Chemical Composition & Mechanical Properties :

| Grade | Chemical Composition | Mechanical Properties | ||||||

| C | Mn | Si | S | P | Yield | Tensile | Elongati | |

| Strength Mpa | Strenth Mpa | -on % | ||||||

| Q195 | 0.06-0.12 | 0.25-0.50 | ≤0.30 | ≤0.045 | ≤0.05 | ≥195 | 315-430 | ≥33 |

| Q215 | 0.09-0.15 | 0.25-0.55 | ≤0.30 | ≤0.05 | ≤0.045 | ≥217 | 335-450 | ≥27 |

| Q235 | 0.12-0.20 | 0.30-0.67 | ≤0.30 | ≤0.045 | ≤0.04 | ≥235 | 375-500 | ≥26 |

| Q345 | ≤0.20 | 1.00-1.60 | ≤0.55 | ≤0.04 | ≤0.04 | ≥345 | 470-630 | ≥22 |

1. Steel Scaffold Tubes

- Galvanized Steel Tubes: These are the most common type of scaffold tubes used due to their strength and durability. The galvanization process involves coating the steel with a layer of zinc, which provides excellent corrosion resistance, making them suitable for outdoor and long-term projects.

- Black Steel Tubes: While not as corrosion-resistant as galvanized tubes, black steel tubes are still widely used in scaffolding. They are typically used in indoor or temporary applications where exposure to the elements is minimal.

2. Aluminum Scaffold Tubes

- Lightweight and Corrosion-Resistant: Aluminum tubes are favored for their lightweight properties, which make them easy to transport and assemble. They also offer good corrosion resistance, making them suitable for environments where moisture is a concern.

- Ideal for Mobile Scaffolding: Due to their lightweight nature, aluminum tubes are often used in mobile scaffolding systems that require frequent movement and reconfiguration.

3. Fiberglass Scaffold Tubes

- Non-Conductive: Fiberglass tubes are non-conductive, making them ideal for use in environments where electrical safety is a concern, such as power plants or facilities with high-voltage equipment.

- Chemical Resistance: These tubes are also resistant to chemicals and corrosion, making them suitable for use in industrial or chemical processing environments.

4. Composite Scaffold Tubes

- Advanced Material Technology: Composite tubes, often made from materials like carbon fiber, offer high strength-to-weight ratios and excellent durability. They are used in specialized applications where traditional materials may not suffice.

- Cost Considerations: While more expensive than traditional materials, composite tubes provide unique advantages in terms of performance and longevity.

5. PVC Scaffold Tubes

- Lightweight and Cost-Effective: PVC tubes are lightweight and inexpensive, making them suitable for certain temporary or low-load applications.

- Limited Load-Bearing Capacity: Due to their lower strength compared to metal tubes, PVC tubes are typically used in non-structural applications or as protective barriers.

Material/characteristic:

1.Abtersteel is committed to long-term development, creating high-quality products and services, with the same pursuit of quality and service, stable, strong, long-term cooperation raw material suppliers, such as Haigang, Yurunde, etc., to maximize the consistency and stability of materials, product appearance and internal quality;

2.Raw materials grade : Q195, 235, 235B and Q345…

3.The zinc coating can customized for customers, up to 280 grams.

4.The purity of zinc wire is 99.99% zinc content with high purity.to remain the pipe welded seam antirust.

5.The diameter of zinc wire is 1.5mm which has great protection for welding.

6.The salt spray test can satisfy at least 8 hours without corrosion.

7.In the passivation process, we have own invention patents – galvanized pipe passivation liquid automatic spraying system to ensure even adhesion, high passivation efficiency, beautiful appearance.

8.In November 2014, it was recognized as “Tianjin Famous Trademark” by Tianjin Market and Quality Supervision Committee. The steel pipe produced and sold by the company was rated as “Tianjin Famous Brand Product” by Tianjin Municipal Government. and keep for many years.

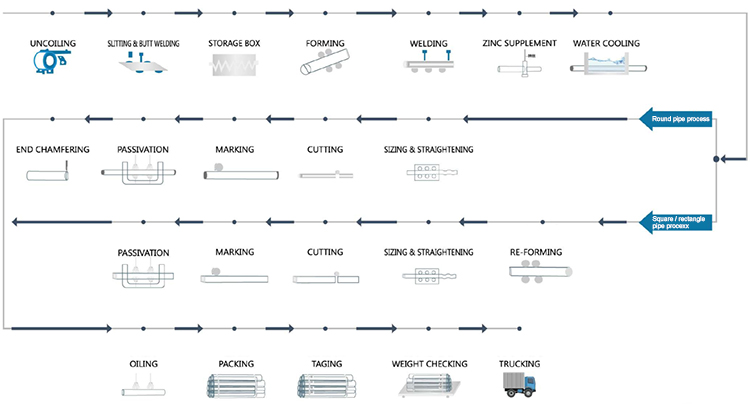

Production processes:

Five Comparative advantages:

1.Thailand, we have the lowest anti-dumping in China.(3.22%).

2.Factory and experimental test center to achieve cost and quality control.

3.Processing lines, can satisfy various requests of customers. Producing and processing one-stop service.

4.Is the top five in Tianjin.

5.We have been cooperate with Alibaba for 11 years, we are gold supplier and assessed supplier, we are one of first batch of companies do exporter in this industry.

All items of our products and related tests as follow :

1.ERW black round pipe (ASTM A53,GB..)

2.Weld black square/rectangular pipe(ASTM A500,GB,…)

3.Hot dip galvanized round pipe (BS 1387,ASTM A53,GB ,…)

4.Hot dip galvanized square/rectangular pipe(ASTM A500,GB…)

5.Pre-galvanized square/rectangular/round pipe,cold rolled black annealed or bright finished pipe.

6.Spiral steel pipe

7.Seamless pipe (ASTM A53,A106B,)

8.Oval pipe in galvanized and black surface

9.LTZ… special sizes pipe

10.Steel prop , steel plank,steel scaffolding pipe and accessories… steel constrctution material

11.Steel angle, Flat bar,round bar,sqaure bar,

12.H,I,U,C,T,Y,W…steel beam/channel

13.Deformed steel bar

14.Hot rolled& cold rolled steel sheet/coil in black,galvanized,color coated surface.